This project was completed during my junior year for the ‘Product Design’ course. The aim of the project was to create a product that could automate the sorting process of recyclable plastic, glass, and aluminium containers. The project arose as current, human-based sorting causes the contamination of waste, thus making it unrecyclable, so an automated approach would be beneficial to reduce this issue. Our four-person group decided to achieve this goal by implementing the use of various sensors alongside a four-bar linkage system and belt and pulley mechanism to sort the waste.

I primarily worked on the material identification part of the project, this being sensor usage and code. Inductive proximity sensors were used to detect the aluminium waste, while load cell sensors were used to differentiate between plastic and glass, all coded using the Arduino IDE and Arduino UNO boards. In addition, the motors for the mechanical system were also controlled using an Arduino UNO board, having a connection between the sensor and motor boards to share data.

Although our project was successful in recognising the desired materials 92% of the time (tested 100 times), it did not always sort it properly due to issues with the four-bar mechanism as parts would slip through. In addition to this, the load cells were quite sensitive and sometimes would produce erroneous results due to inadequate calibration.

In addition to this, this project demonstrated the need for iterating designs and working at smaller scales before implementing systems in a full-scale setup. If our team had iterated on smaller models we may have been able to catch issues with our design sooner and correct these, thus preventing larger issues with our final design.

Automatic Trash Sorter

Collaborators

Skills

Sensor Selection

Prototyping

Arduino (motor and sensor control)

Product Diagrams

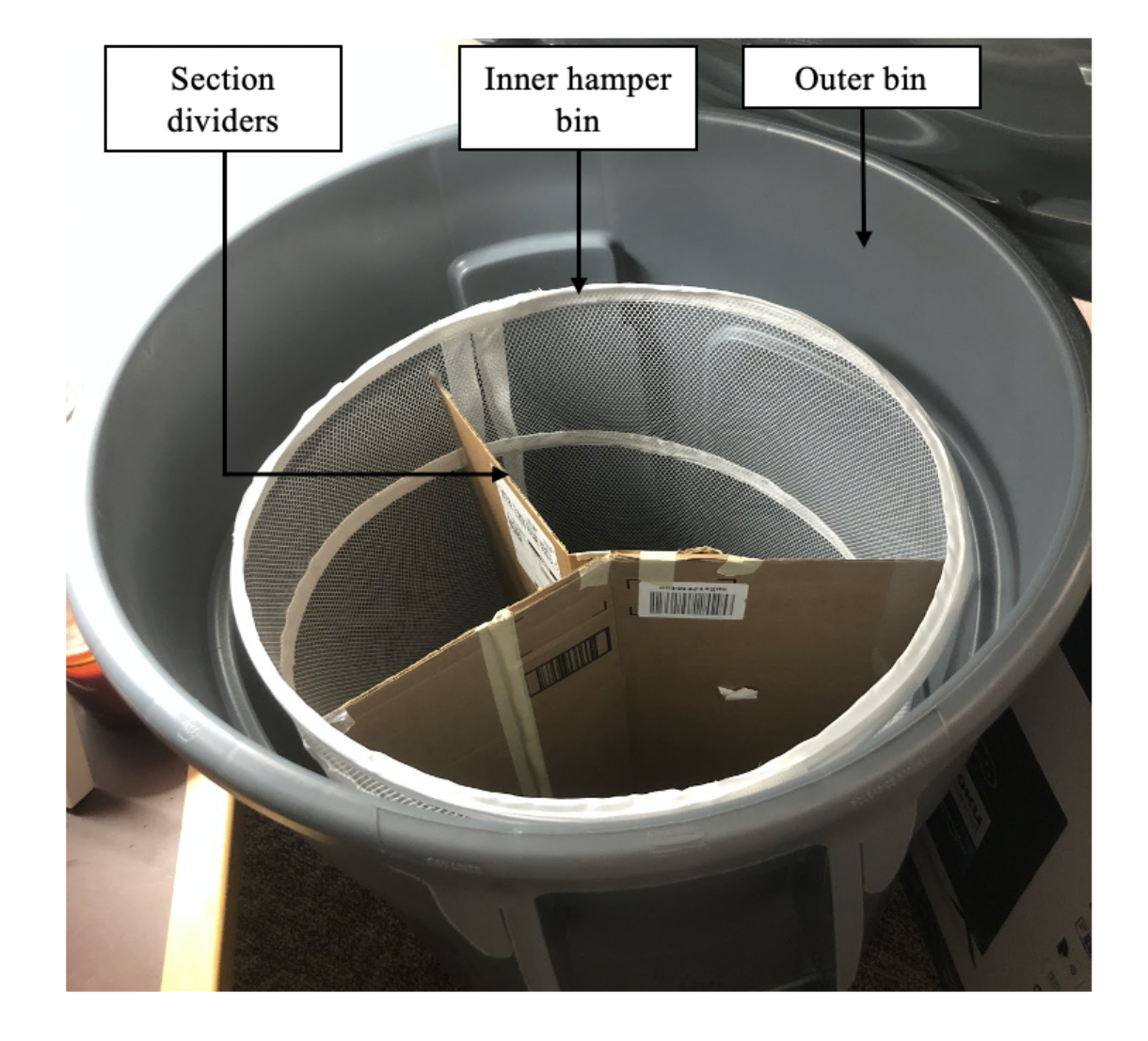

The images in this section show the diagram of the mechanical system and the sensor setup used in the project. The video shows a demo of the machine sorting a metal can.